十大正规赌网站“材子论坛”暨青年学术沙龙系列报告会第148场成功举办

发布时间:2016-01-11 作者:十大正规赌网站研究生会 来源:公司材料院 浏览次数:

2015年01月08日星期五下午15:30,十大正规赌网站(中国)有限公司青年科协联合院研究生会举办的青年学术沙龙第148场在特冶楼229学术活动室顺利举行。十大正规赌网站梁叔全教授、郑子樵教授、李红英教授、陈志国教授、李劲风教授、江勇教授、陶辉锦副教授及数十位研究生到场参加。

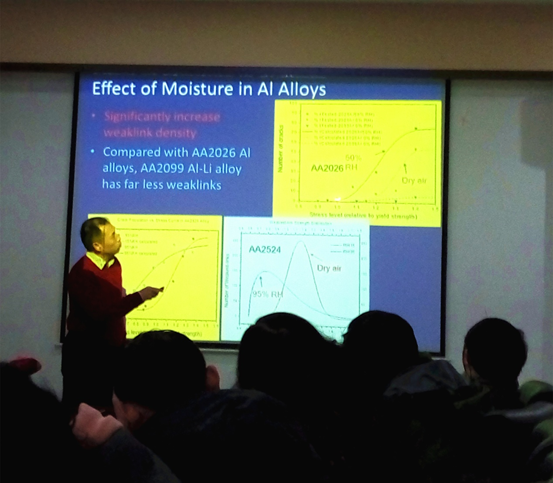

美国肯塔基大学化工与材料工程系翟同广教授作了题“Microstructure-based models for simulation of short fatigue crack initiation and growth in 3-D”的学术报告,报告会上,翟同广教授就铝锂合金的短疲劳裂纹的起源及生长的微结构三维仿真模型等最新研究成果作了介绍。其研究团队通过织构及晶粒结构对短疲劳微裂纹模型的仿真,发现晶粒结构及织构严重影响短疲劳微裂纹的寿命,并以此创新裂纹产生、裂纹测试等,首次定量分析了晶粒大小对短疲劳裂纹的影响,并且对合金材料的服役寿命进行了更精准的预估,成功刷新材料科学相关领域世界前沿研究水平。沙龙最后,翟教授详细解答了我司师生提出的难点问题,并与郑子樵等教授展开了热烈讨论,碰撞出思想的火花。

此次翟教授来院开展学术交流活动,拓展了我司师生的国际视野,对院材料中心延展研究方向具有重要借鉴意义。

报告人简介

Professor Zhai obtained his bachelor degree in metal physics from University of Science and Technology Beijing in 1983. He was a recipient of Sir Run Run Shaw Scholarship for his PhD study in Materials Science at University of Oxford, and received his D.Phil. degree in 1994. He was a recipient of US-National Science Foundation CAREER Award, and promoted to a tenured Associate Professor in 2007. He has been the principal investigator of 14 research projects supported by US-NSF, DOD and materials industry.

He has established an active and productive research laboratory for materials processing, properties, and characterization at University of Kentucky. He has so far published over 100 papers (70 of them SCI-indexed), supervised 12 PhD students, 2 postdoctoral researchers, and 15 visiting scholars.

Significant scientific contributions and findings: 1)identification of net irreversible slip accumulation in surface being the mechanism for fatigue crack initiation in pure metals; 2)development of experimental methods: a) to characterize fatigue weak-link density and strength distribution in engineering alloys; and b) to measure resistance of grain boundaries to fatigue crack growth; 3) establishment of microstructure-based models for quantification of fatigue crack initiation and early growth; 4) identification of formation mechanisms for P texture in Al-Mn alloys and 5) for α phase dispersoids in 6000 series Al alloys, etc.